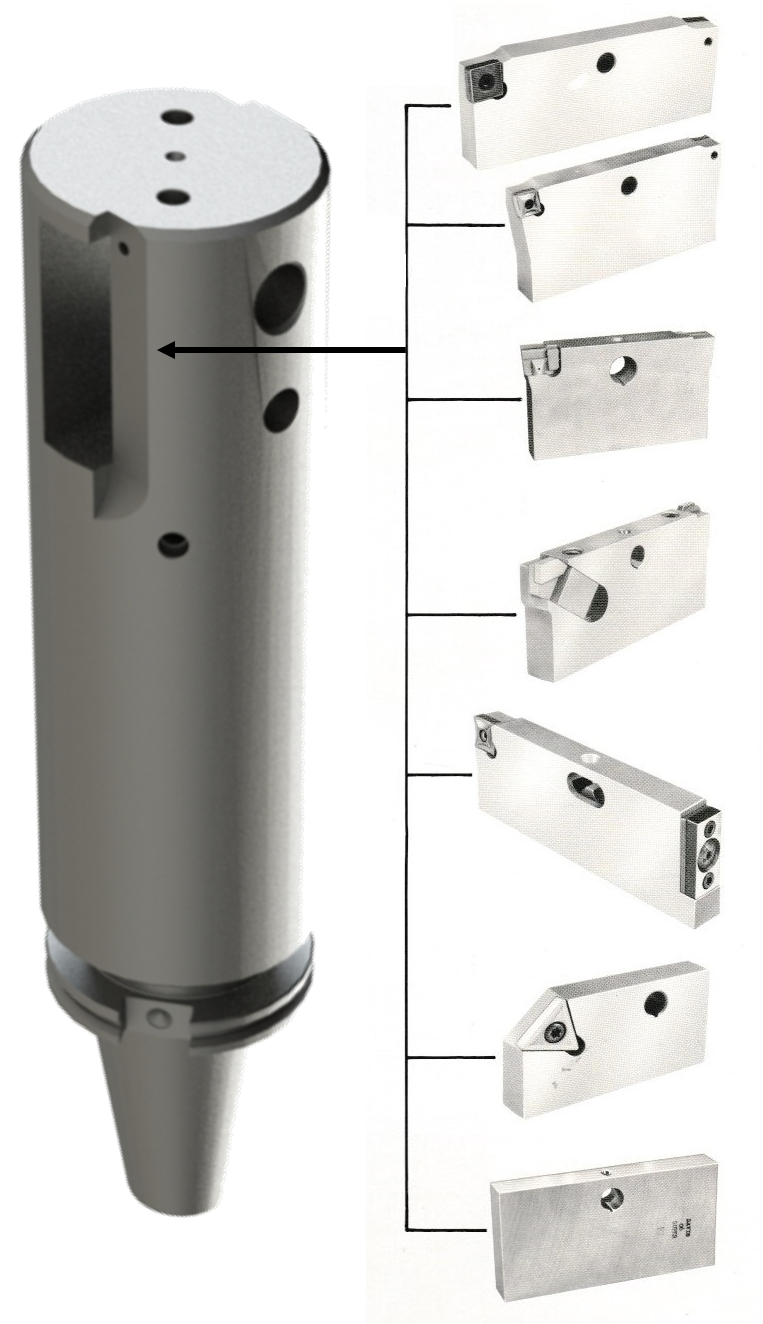

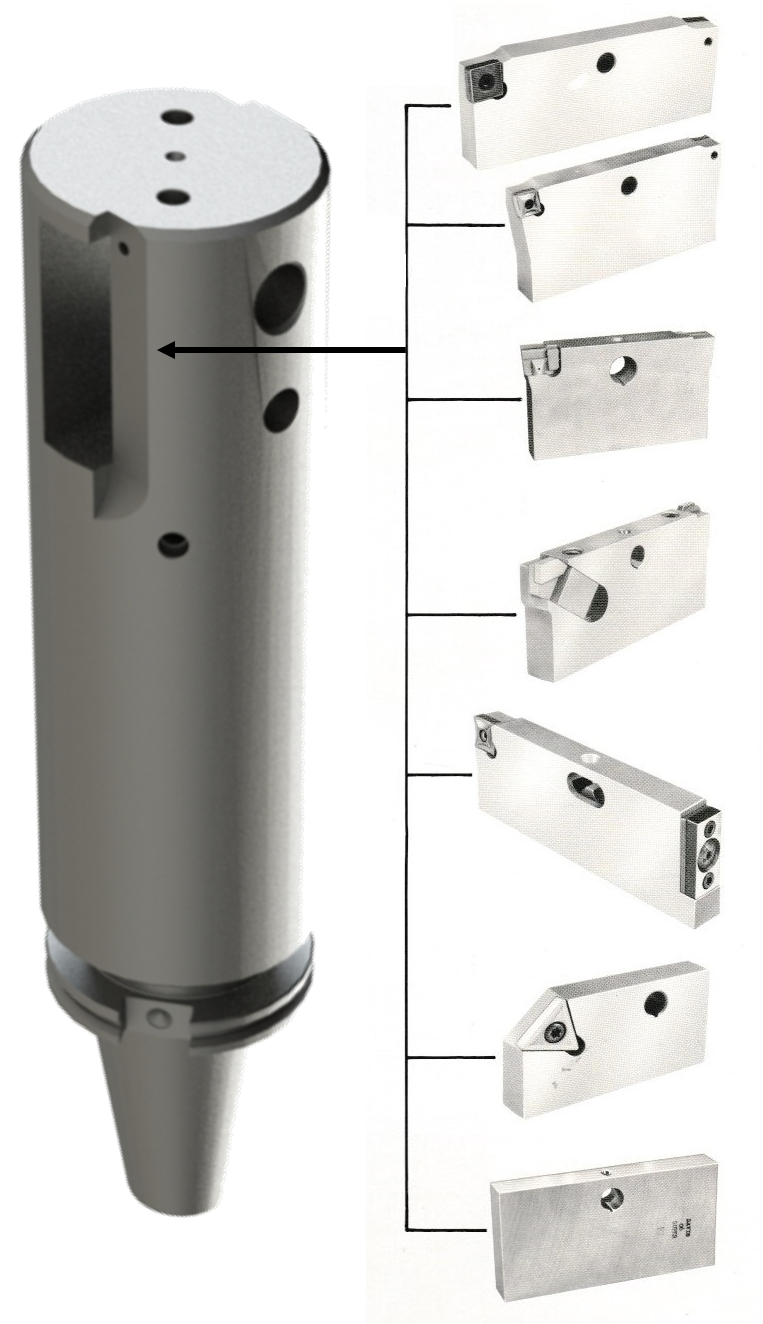

The Davis Block Type Boring Tool System

Increases productivity and reduces tooling costs for vertical and horizontal boring machines and machining centers.

Company Overview Brochure

DownloadDavis Interchangeable Block-Type Cutters

INTEGRATED SUPPLY PROGRAMS